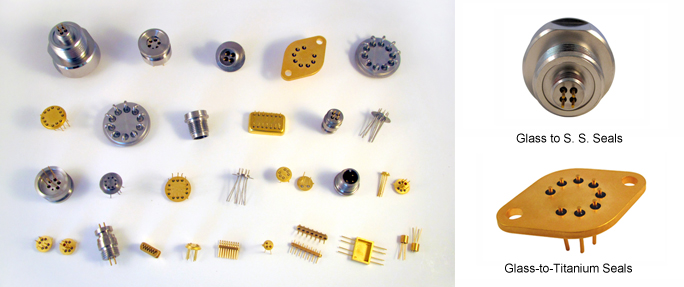

Complete Hermetics, a custom prototype designer and manufacturer of hermetic seal and hermetic feedthrough. We specialize in glass-to-metal sealing and ceramic-to-metal seals for electrical feedthrough and high vacuum feedthrough applications.

Complete Hermetics formulates a multitude of glass feedthrough and ceramic feedthrough materials successfully for various hermetic seals and hermetic feedthru applications. We can custom make those electrical feed through in a wide variety of terminals, from high voltage to low current capacities.

Our customers rely on Complete Hermetics for their hermetic sealing qualities. Our glass-to-metal seal and ceramic-to-metal seal are custom built to or beyond your design specifications.

Glass to Metal Seals & Feedthroughts

Complete Hermetics provides commercial and in house custom seals on compression and match sealing glasses

commonly used in Electrical Feedthru and High Vacuum Feedthru. Typically glass to metal seals are divided into: Compression Seals and Matched Seals.

Compression Seals

Compression Seals: When the CTE (Coefficient of thermal expansion) of the header body or housing greatly exceeds

that of the glass or electrodes, the outer housing components shrink and mechanically compresses against the glass

to form a compression seal. Steel and Alloy 52 is a common combination of materials to form a compression seal.

• Body Materials: Cold rolled steels, Stainless steel, Inconel, etc.

• Glass Materials: Corning 9010/9013 (Alkali Barium), Soda lime, Lead silicate, etc.

• Electrodes Material: Alloy 52, Copper Cored 52 Alloy, Alloy 42, etc.

Typically Compression Seals withstand temperatures ranging from -250°C to 400°C. Allowable operating temperatures

would be from -60°C to 200°C under thermal cycling and shock.

Matched Seals

Matched Seals: When the CTE (Coefficient of thermal expansion) of the body or housing material matches the CTE of the

glass or electrode material a matched seal is formed. The hermetic seal is made by forming a bond through wetting and chemical reactions between the glass and metal. Kovar is the most commonly used material for matched seals.

• Body Materials: Kovar, Alloy 42, Tungsten, Molybdneum

• Glass Materials: Corning 7056 (Alkali Borosilicate)

• Electrodes Material: Kovar, Alloy 42, Tungsten, Molybdneum

Typically Matched Seals maximum allowed temperature is limited by the glass material strain point.

Pin and body assemblies can be plated for better corrosion resistance, wire bonding and soldering abilities.

Plating Options

• Gold Plating

• Silver Plating

• Electrolytic and Electroless Ni Plating

• Tin Plating

Application

Glass seals are effective in sealing hermetically during severe changes in temperature, pressure and humidity compared to O-ring or epoxy seals. Furthermore, glass seals are a cost effective hermetic sealing solution compared to ceramic seals and employed on broader industrial applications.

Hermetic Seal Properties

• Hermeticity: up to 1x10-9 atm cc/sec He

• Insulation Resistance: Typically exceeds 1 giga-ohm @ 100 VDC

• Mechanical Strength: up to 20,000 psi with proper design and processing

• Dielectric: Dielectric can withstand voltage depending on joint geometry and glass material selected. Below are some typical glass values

- Barium AlKaLi: 6.3

- Borosilicate: 4.9

- Soda Lime: 7.2

Ceramic to Metal Seal & Feedthroughs - Please refer to Ceramic-to-Metal Section