Complete Hermetics specializes in challenging brazing and soldering solutions, whether it is small, thin, and/or

reactive material. Our serviced components are built to withstand extreme temperatures and both harsh and

chemically hazardous environments.

• Vacuum Brazing

• Active Metal Brazing

• Hydrogen Brazing

• Reactive Air Brazing

• Ceramic Metallization

• Modeling and Simulation

• Fixture Tooling Design

• Stress/Reliability/Failure Analysis (Modeling and Characteristics)

• Precision Machining/Metallization of Advanced Ceramic Components for Electric,

Mechanical and Vacuum Applications

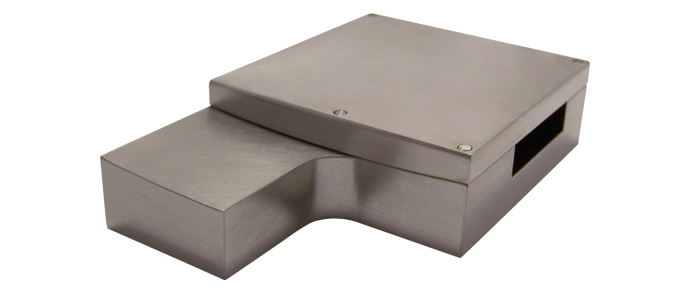

• Precision Fabrication of Metal Components for Medical and Aero/Defense Applications

• Hermetic Assemblies for Optical/Telecommunication Applications

• Solid Oxide Fuel Cell (SOFC) Stack Seals/Fabrications

Typical Ceramics for Brazing & Soldering

• AlN, BeO, Si3N4, SiC, AlSiC, BN, ZrO2, YSZ, YAG

• Polycrystalline Alumina (94%-99%)

• Graphite

• Ruby

• Sapphire (100% Alumina)

Typical Braze Alloys

• Gold and its Alloys

• Silver and its Alloys

• Copper and its Alloys

• Other

Typical Metals/Alloys for Brazing

• Nickel, Ni Alloys (Monel, Alumel) and Super Alloys

• NiFe Alloys and NiFeCo (Kovar)

• Copper and Copper Alloys (CuNi)

• Molybdenum, Niobium, Tungsten

• Platinum, Titanium

• 300 Series SST (304, 316, 321) and Inconels

• 400 Series SST (410, 430)

• NiTi and Other Shape Memory Alloys